Reverse Circulation Drilling Systems

RC drilling is the ideal method for large diameters and hard rock drilling. The main advantage in foundation work is having control of the spoils (cuttings).

Products

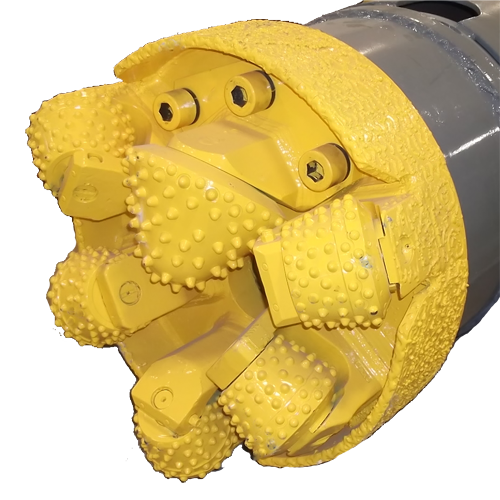

RC Drills

Specialty reverse circulation drills designed for use on Berminghammer lead systems. Typical applications are hard rock and case advance drilling.

RC Swivels

High quality swivels designed to adapt traditional European drill rigs for reverse circulation rock drilling. From 24” (with down-the-hole-hammers) through 120" diameter cluster drills and everything in between.

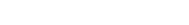

Drill String

The industry’s most durable and versatile reverse circulation drill string. 2 to 3 separate drilling passages to accommodate mixtures of air, water and drilling foams. Spoils return passages up to 9.75 inches in diameter.

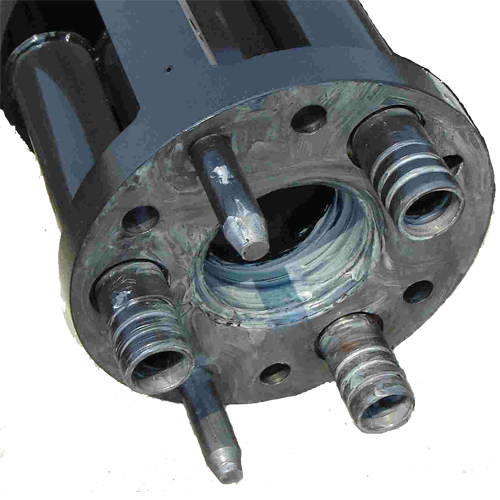

RC Rotary Bits

Made in Canada, these high-quality conventional rotary bits are for rock around 100-200 MPa.

Stand Alone Valves (SAV)

Stand alone valves control the hydraulic functions of Berminghammer equipment. Connect the SAV to a power pack and you will be able to run Berminghammer’s drills, leads and accessories. Comes with an electronic controls suite for your operator.

RC Drilling Equipment

For rock drilling and rock socketing, Berminghammer has a wide variety of equipment available for sale or rent. Berminghammer reverse circulation drilling equipment is suited to all rock drilling methodologies; conventional rotary, down-the-hole hammer or cluster drill.

The Berminghammer line of Reverse Circulation Drills were developed in-house by a joint effort of the Construction division and Berminghammer. It is well suited for rock drilling up to 2.5 meters in diameter and pairs seamlessly with Berminghammer’s industry tested lead systems.

To understand the advantage of reverse circulation drilling one must understand that direct circulation is limited because the method simply lets water and cuttings come to the surface and spill over the side of the pile free flow to the lowest point in the area.

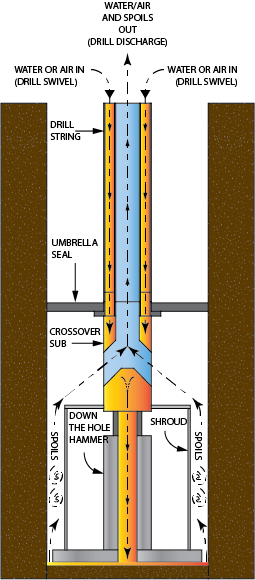

The main advantage of RC Drilling in foundation work is having control output of the spoils (cuttings). This is done by forcing the cuttings back up the inner tube of the drill string and out the top of the drill through discharge hose to the desired disposal location.

For use with:

- Down-the-hole-hammer (sockets and case advancing)

- Cluster drill

- Conventional RC bits

Advantages:

- Congested jobsites

- Environmentally sensitive areas

Berminghammer Reverse Circulation Drills

Berminghammer drills represent the most ruggedly designed and extensively field-tested all-purpose drills in the foundation industry. Berminghammer drills can be used in almost every type of drilling application and specialize in Down-the-Hole- Hammer applications. There is simply no better choice for foundation contractors than a Berminghammer drill.

Productive drilling occurs when the majority of the time spent on-site is devoted to actually drilling. Many competitor drill rigs involve time draining activities such as: long rig-up times, difficult and time consuming pile placement, adding more and splicing piles. Berminghammer's drilling systems are intelligently designed to minimize these deficiencies and maximize production rates through hard rock. Berminghammer’s leads are most often designed to allow for one stroke, meaning that there is no slow installation of additional drill string and no pile splicing necessary. Berminghammer drilling systems are the most maneuverable on the market thanks to the patented combination with the Vertical Travel Lead. This maneuverability greatly decreases setup time so that the majority of time is spent drilling. The Berminghammer lead systems in conjunction with our hydraulic drills, drill string, impact hammer and custom rotary bits allow for execution of drilling, driving and rock socketing efficiently and seamlessly.

Reverse Circulation Drilling

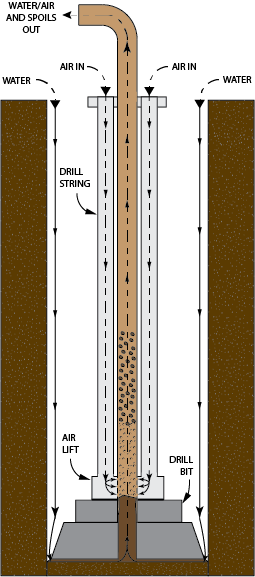

‘Reverse Circulation’ drilling involves the supply of air down through the drill-string to decrease the ‘effective density’ of the water in the center of the drill-string. Operating much like an ‘air-lift’, the drilling spoils are carried out of the hole through this rising column lower-density air/water mixture (see Figure). Reverse Circulation requires that the outer annular area of the casing be kept full of water in order to provide the hydraulic head required to effectively ‘push’ the central column of air/water/spoils up and out of the hole through the central pipe of the drill-string.

Reverse Circulation is an effective drilling technique for a wide range of hole diameters including very large holes – up to 3-m diameter and larger. It is also effective for very deep holes, and holes drilled into hard-rock.

Reverse Circulation is able to control/direct the drilling spoils by simply directing the discharge pipe to the desired site location or even to a dedicated barge (for environmentally sensitive, overwater applications). This cannot be accomplished with direct circulation which allows water and cuttings to spill out of the top of the pile.

Reverse Circulation can be used in conjunction with rotary drilling bits as well as Down-the-Hole-Hammer applications. The Berminghammer Reverse Circulation Drills are particularly well suited to Down-the-Hole-Hammer applications due to their simple, rugged design and construction.